In addition to booster pumps, submersible pumps are also a popular choice among consumers for drainage, well water extraction, pond water pumping, river/stream intake, etc., catering to a variety of needs ranging from domestic, agricultural to industrial purposes.

In today’s market, submersible pumps are available in a wide variety of types, brands, product qualities, and prices, resulting in significant differences among them.

So, if you’re inexperienced, it can be challenging to choose a high-quality product that best meets your needs.

Understanding this, today we’d like to introduce in detail, an overview of the submersible pump line. As well as introducing you to quality submersible pump brands, which have been globally recognized for their reputation.

What is a submersible pump?

A submersible pump is designed with a special construction that allows it to be submerged deep into liquid without worrying about water or fluid entering the pump’s electric motor.

Most submersible pumps are designed with a motor that is fully protected by a sealed oil-filled chamber, which is waterproof, ensuring the motor operates safely, continuously, without concerns about damage, leakage, or rust.

Due to its special design allowing submersion in liquids, this type of pump is widely used in practice, from pumping water in mines, submerged under the sea or riverbeds, to wells, ponds, and more. It’s also utilized for pumping wastewater in residential areas, flooded basements, and other similar environments.

Why Use Submersible Pumps?

As you may know, submersible pumps are designed to be submerged directly into the liquid to be pumped. This is particularly useful for rural households relying on well water, where there is no connection to municipal water sources like in urban areas. Without a powerful submersible pump to draw water to the surface, wells would essentially become unusable.

Furthermore, this type of pump is commonly used for household wells due to its notable advantages:

There’s never a need for primer or water bait.

Most modern pump models are designed to operate safely, limiting damage from corrosion. The pump needs to be carefully electrostatically painted, and before operating, users must prime and fill it with water.

Priming these types of pumps can indeed be time-consuming and require effort from the user.

On the other hand, submersible pumps, by design, are submerged directly into the well or fluid, ensuring that they are always immersed and filled with water. As a result, you never need to prime the pump to start its operation.

This will save you a lot of time and effort, especially if you are a user with little experience or understanding of well operation.

Energy saving

Because these pumps are submerged in the fluid to be pumped, they don’t require much energy to draw water into the pump chamber. The water is continuously pushed into the pump by the natural pressure of the water.

Unlike many surface-mounted pumps that rely on suction or lift force to draw water, which can consume a significant amount of electrical energy, submersible pumps operate more efficiently due to their placement beneath the surface of the water.

When using a submersible pump, your electricity bill will be minimized to the lowest possible level. Additionally, using this type of pump will also reduce carbon emissions indoors, which can have environmental impacts.

For households living in areas with unstable or unreliable power sources, a submersible pump is also an ideal choice. Many submersible pump models can operate even when the voltage drops, making them suitable for such environments.

Not easily susceptible to interference or cavitation.

When a pump operates without enough water in the pump chamber, the impeller will generate thousands of tiny air bubbles at high pressure.

When these bubbles collapse, the shock waves they create can damage the pump, affecting the impeller and the inner surface of the pump chamber.

This phenomenon is often referred to as cavitation, which can quickly deteriorate and damage pumps placed on the surface if not properly cared for and maintained.

On the contrary, submersible pumps are submerged in water and continuously filled with water, so they are rarely affected by cavitation. This type of pump is very useful for users with less experience, ensuring that the pump can operate steadily, safely, and achieve optimal performance.

The pump operates with extremely low noise levels

With some pumps designed with high noise levels, it can be quite discomforting to use, especially if you intend to operate the pump at night.

As for submersible pumps, they generally operate much more quietly compared to surface-mounted pumps because the noise they generate is largely absorbed by the surrounding water.

(if the pump is placed at a certain depth, there is virtually no noise)

This is particularly useful when the pump is used in residential areas, especially if your well water source is close to your home or surrounded by many neighboring houses.

Submersible pumps will ensure that you can use your pump anytime, day or night, without disturbing the surrounding area or disrupting your sleep.

Structure and operating principle of submersible pumps?

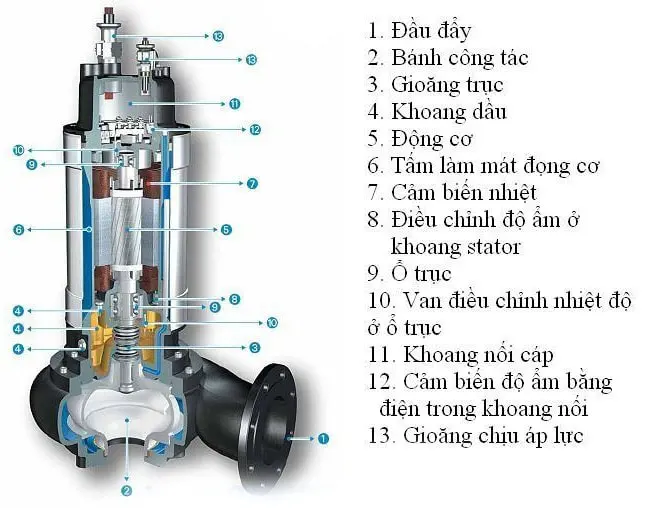

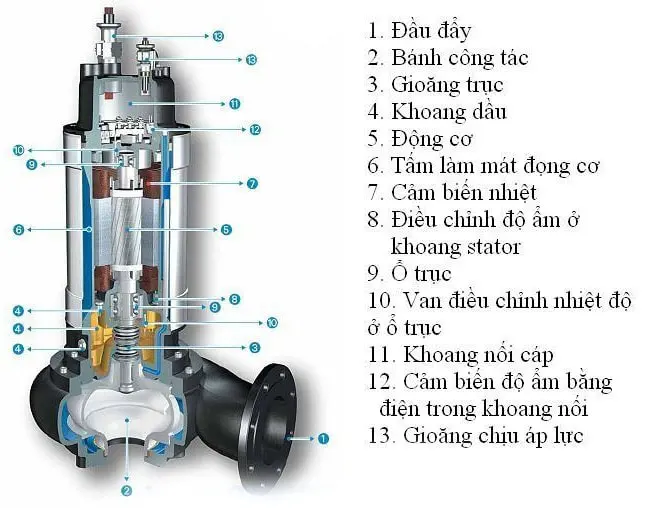

Submersible pumps are a type of pump designed with a very complex structure, requiring high technical expertise. It can be said that these pumps have the most complex structure among the various types of pumps available in the market today.

Because in manufacturing this type of pump, it must be ensured that the pump can “self-protect” itself from external factors such as water pressure, ambient temperature, water leakage, etc.

Due to being designed to meet stringent technical requirements, most submersible pumps on the market can be used continuously for long periods, ensuring stable performance and very high pump longevity.

The structure of a submersible pump?

As you may know, the design of this pump requires stringent quality standards, so the components constituting the pump are made of materials that are highly resistant to oxidation, completely rust-proof, capable of withstanding high pressure, and less affected by external environmental conditions.

The operating principle of a submersible pump?

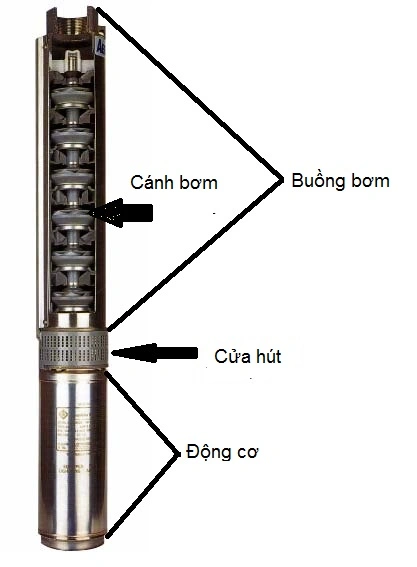

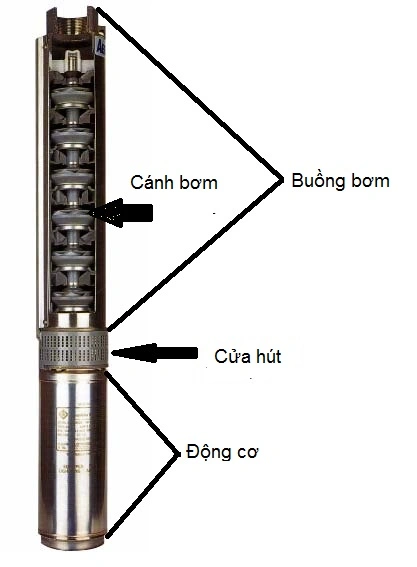

Most submersible pumps nowadays operate on the principle of centrifugal force, meaning that the fluid is drawn into the pump chamber through the suction port. Then, due to the centrifugal force generated by the impeller, the fluid is pushed out through the action of the blades, directing it straight into the pipeline, thus forming the pumping process.

Furthermore, some types of positive-displacement submersible wastewater pumps operate on the principle of creating a vacuum environment. This means that when the pump is in operation, it creates a vacuum environment within the pump body, then pushes the liquid to be pumped from below based on pressure and pressure differential.

Submersible pumps include what types?

Based on their structure and specific applications in practice, this type of pump is generally divided into two main categories: Submersible well pumps and submersible wastewater pumps.

Submersible well pumps

Submersible well pumps (also known as borehole pumps) are designed with a vertical, cylindrical structure and are used to draw water from deep wells or boreholes. They are very convenient for use in rural areas and highland regions.

Most types of submersible well pumps typically have a high discharge head, capable of both deep suction and high discharge, ranging from 100 to 200 meters.

Today, manufacturers continually improve upon advanced and modern technologies, leading to widespread applications of these pumps across various aspects of life, including civil, agricultural, and industrial sectors.

Submersible wastewater pumps.

These pumps play a significant role in industrial, agricultural, and household settings.

Just like most other types of submersible pumps, submersible wastewater pumps when used, they are completely submerged in water, playing a crucial role in keeping your basement dry and preventing waterlogging. They are particularly suitable for areas prone to flooding due to heavy rainfall or storms.

These pumps can be used for both clean and dirty water. Additionally, some models are specially designed to be installed either on the water surface or on dry land.

This type of pump is widely used in various practical applications, including agricultural purposes (irrigation for farming, livestock), in construction industries (bridges, gas stations, etc.), for pumping sludge, treating wastewater systems, pumping clean water, firefighting systems, and more.

Applications of submersible pumps in real life?

As you know, submersible pumps are designed with a housing that can be directly immersed in the liquid to be pumped, allowing the pump to dissipate heat quickly and significantly reducing the risk of damage, overheating, or explosions. Therefore, these pumps are used quite efficiently and find extensive applications in real-life scenarios.

These machines are widely utilized, from drawing water from boreholes for household purposes (submersible borehole pumps), to lifting water to high-rise buildings, meeting and serving water needs in industrial and agricultural production.

Submersible pumps are particularly useful for suction and discharge of water in high-altitude areas and hilly regions. As you know, in high mountainous regions where the groundwater level is considerably deep, finding and extracting groundwater for usage poses significant challenges. Moreover, the groundwater streams in these areas often have low and irregular flow rates. Therefore, using conventional pumps to lift water becomes quite difficult, especially during dry seasons.

For this reason, installing submersible borehole pumps will effectively address the water supply issue.

In our country, particularly during the rainy season, flooding occurs frequently, causing a lot of inconvenience for people. In such cases, submersible wastewater pumps are also an ideal choice for water drainage, helping to mitigate flooding and reduce its impacts.

Additionally, submersible pumps in general are often designed with high power and strong motors, making them suitable for application in most industrial and agricultural facilities, as well as for irrigation purposes.

Key considerations when buying a submersible pump you should know?

Regardless of which type of pump you choose to buy, not just submersible pumps, you need to pay special attention to three important parameters: flow rate, power, and head.

To accurately determine these parameters, the first step is to precisely identify your specific real-world usage needs. The more accurately you define your usage needs, the more you can mitigate risks during operation and minimize unnecessary damage, which could lead to wastage.

Pump flow rate

Typically, each type of submersible pump is designed with a different flow rate capacity. Therefore, depending on the requirements of your project or construction site, you can select the most suitable pump flow rate.

If you lack experience in pump usage, it’s best to contact us and outline your usage needs so that we can assist you in selecting the most suitable submersible pump model.

Pump head

This is also a crucial factor when choosing a pump because if you buy a submersible pump with an inappropriate head, the efficiency of its usage will be low, resulting in wasted energy consumption, and sometimes the pump may not be usable at all.

For example, if you purchase a borehole pump intended for a well with a height difference ranging from 2 to 10 meters, but you choose a pump with a head of 8 meters, then it’s certain that the pump will not be able to lift the water, resulting in loss and wastage.

Pump power

The pump power is also an important factor that can help you save a significant amount of electricity consumption.

Suppose you have researched and are comparing two products that are suitable in terms of flow rate and head requirements. However, if one product has a power rating of 2 kW and the other has a power rating of 2.5 kW, you can simply choose the pump with the lower power rating to maximize energy savings while still ensuring optimal pump performance.

Besides the three important factors mentioned above that require special attention when selecting a submersible pump, you should also consider the following factors to ensure that you purchase the best pump, thereby maximizing the pump’s lifespan.

- Power supply voltage: you need to determine the electrical current in your household. (usually 220V), and based on that, refer to and select a suitable pump model because if you choose a pump with an incompatible current rating, it definitely won’t be usable.

- Pump construction materials: Currently, most submersible pumps are made from stainless steel or cast iron, which provides excellent corrosion resistance. However, if you’re purchasing a pump for use with highly corrosive wastewater, it’s best to choose pumps made of stainless steel or those that have undergone a special treatment process to prevent corrosion and damage during use.

- Pump brand: Selecting a submersible pump from a reputable brand with a proven track record in the market is also a crucial consideration. This ensures that the pump operates reliably, enhances its lifespan, and provides reliable warranty and after-sales support. Currently, there are many quality submersible pump brands such as Franklin Electric, Tolsen, Tsurumi, Pentax, Ebara, Wilo, and more.

Important considerations when installing and using submersible pumps?

Similar to other types of pumps in general, to ensure stable operation, optimal efficiency, and maximize the lifespan of the pump, it’s important to pay special attention to installation and usage.

Before proceeding with the installation, you should thoroughly review and verify whether the overall design and technical specifications of the pump match those specified in the designer’s catalog and meet your actual usage requirements.

It means you will check the machine model, specifications regarding flow rate, head, etc. You’ll also verify the recommended power supply to ensure that it aligns with the electrical source available in your household.

Check if any accompanying accessories with the pump are missing, such as check valves, discharge valves, flanges, flexible couplings, etc.

You should also pay attention to inspecting the location where the pump will be installed, ensuring safety regarding electrical wiring, suction heads, discharge heads, etc.

Furthermore, you should also check the insulation resistance of the motor and cables submerged in water, measure the insulation resistance between the ground and each phase of the motor, and between motor phases using an insulation resistance meter. The displayed reading on the meter should not be less than 20 mΩ.

Considerations when installing submersible pumps

- The pump should be installed in a location adjacent to a tank, pond, or where the water level is low to avoid the pump operating in dry or low water conditions.

- When installing a submersible pump, you should never use a cable for suspension; instead, use a chain or rope for hanging the pump.

- You must hang the pump vertically to minimize vibrations. If the water reservoir has flowing water, it’s advisable to install a suitable support frame.

- Choose the water pipe for the pump that is most suitable, ensuring that the pipe is not blocked and that the flow rate is always consistent. It’s best to avoid sharp bends or kinks in the pipe to maintain a stable water flow.

- Submersible pumps without automatic operation will not have an automatic float switch system. Therefore, you must regularly monitor the pump while it’s running. It’s not advisable to let the pump operate for long periods with the water level near the minimum level. To prevent the pump from running dry or in low water conditions, you should consider installing an automatic operation system to maintain a safe water level consistently.

After completing the installation of the submersible pump, it is essential to thoroughly test and inspect it to ensure stable, safe, and efficient operation.

Notes when using submersible pumps

To ensure the stable operation and increase the lifespan of the submersible pump, you should also pay attention to and adhere to the following requirements while using it:

- Before plugging in the power to operate the pump, you should carefully check whether the electrical source in your household meets the voltage requirements of the pump. Because if the voltage supplied to the pump is too low or too high, it can cause damage to the pump or prevent it from operating.

- While the pump is operating, you should regularly monitor and check for any unusual signs or strange noises from the pump. If you notice any unusual signs or behaviors, you should turn off the power, inspect, and address the issue immediately to prevent unnecessary damage and expenses.

- As a type of pump submerged in water, the electrical cord may come into direct contact with water. Therefore, you should also check whether the electrical cord is damaged or chewed by animals, as this can cause electrical leakage and pose a safety hazard to users.

- You also need to regularly inspect the water pipes leading from the pump to the intended water usage area, ensuring that the pipes are not kinked or leaking, which can result in water wastage.

- Additionally, to minimize the risks associated with using a submersible pump, it’s advisable to regularly inspect and clean the pump to promptly detect any damages and devise a plan for rectification.

Where to buy authentic, reputable, and quality submersible pumps?

In today’s market, there are many dealers and distributors offering a wide variety of models, types, and prices for submersible pumps.

If you’re someone with limited experience in submersible pumps, it can be challenging to choose a reliable and quality supplier, as well as purchase a product that meets your usage needs.

Understanding the concerns and issues faced by users, our company, Hung Viet, has imported and distributed a wide range of genuine submersible pump products from many leading brands worldwide such as Franklin Electric, Tolsen,…

“At Hung Viet, you will purchase quality, genuine products at the best prices on the market.

All of our distributed submersible pump products always come with full documentation proving their origin (CO, CQ). Additionally, we provide reliable warranty and after-sales services, always aiming for your benefits.

By choosing us, you will be assisted by a team of experienced consultants who are dedicated to helping you select the best and most suitable submersible pump model for your needs.

For any inquiries about submersible pumps, water pumps, or related issues, please don’t hesitate to contact Hung Viet for the most attentive advice.

Hung Viet Electronics and Trading Co., Ltd. (HVC)

Specializing in providing solutions, supplies, machinery, equipment, spare parts, raw materials serving industries such as chemical, cement, steel, glass, paper, textiles, food and beverage, construction, transportation, etc.

- Address: Số 5 ngách 6/13 Kim Đồng, Hoàng Mai, Hà Nội

- Phone: +84(0)4 3664 1708

- Fax: +84(0)4 3664 1709

- Hotline: +84 913214096

- Email: sale@hvc-vn.com

- Website:hvc-vn.com

- Working hours: Monday to Friday: 8:00 AM – 5:00 PM; Saturday: 8:00 AM – 12:00 PM