Advantates

- It can be used as an emergency stop device required by occupational safety and health regulations to prevent accidents resulting in injury or death to workers.

- By pulling the wire rope from anywhere on the conveyor, the facility can be stopped immediately, minimizing damage.

- It is also effective for safety measures before work. Activating the pull stop while working around the conveyor prevents the conveyor from being started by mistake. Serious accidents can be avoided.

Features

- 1 unit covers 100m

- Risk assessment design

- Safety design

Operating principle

If you connect wire ropes to both sides of PULLSTOP lever and attach wire ropes along belt conveyor, you can pull the wire rope from anywhere on the belt conveyor to activate the PULLSTOP and stop the equipment in an emergency.

How to use?

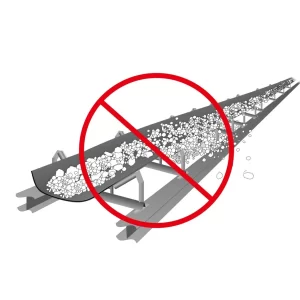

- Determine the mounting position:

Decide on an installation location that avoids falling ore from conveyor or a location subject to large vibrations or shocks. - Mounting:

Provide installation base for the PULLSTOP. It is recommended to install a cover in case of falling mines. The length of the wire rope for operation is up to 50m on one side. - Wiring:

The contact signal is a dry contact. Avoid direct input to motors and sequencers. In addition, “Control Category 4” can be ensured by using safety relay units instead of magnet conductors and relays. - Adjustment:

Specifications: