Advantates

Features

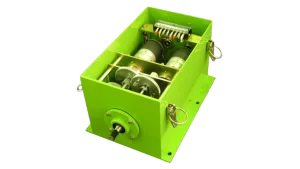

- Selectable transmitter: Transmitter can be selected according to customer’s request, such as current transmitter, potentiometer, synchro transmitter, encoder, and absocoder.

- Cam switch can also be added: Adjust output signal to desired resolution with reduction (speed increase) gear. Cam switch can also be added.

- Plenty of options and customization

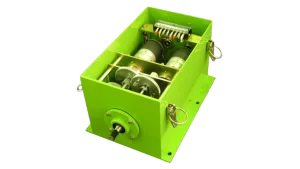

Operating principle

It mainly consists of an input shaft, reducer, and transmitter. When shaft takes in rotation speed from equipment, rotation speed is transmitted to transmitter through the reducer. The transmitter outputs a signal proportional to the number of revolutions and conveys position information.

How to use?

- Determine the mounting position:

Vibration from motors and reducers does not pose problem, but do not install near sources of large vibration such as vibrating screens or vibrating feeders. - Mounting:

- Wiring:

Please wire checking connection diagram. After wiring, securely tighten waterproof connector. - Adjustment: