Advantates

- By detecting belt damage at an early stage and stopping equipment, huge repair costs can be reduced.

- Damage to conveyor belts and equipment can be minimized.

- Production losses can be kept to minimum because recovery work is short.

Features

- Can be used repeatedly

- Easy to install

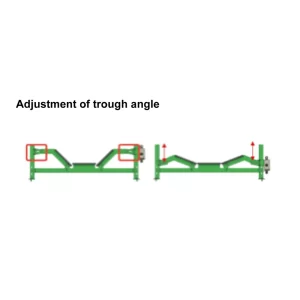

- Adjust according to trough angle on site

- Made to order

Operating principle

Sensor of Belt Tear Detector is tubular with separate positive and negative cables. These cables are energized by converter.

When this tube is crushed by an external force, the positive and negative cables inside come into contact with each other and are detected by conduction.

By placing this sensor next to impact roller under chute, if a foreign object penetrates the belt, the foreign object presses the sensor (tube) and activates the sensor.

How to use?

- Determine the mounting position:

- Mounting:

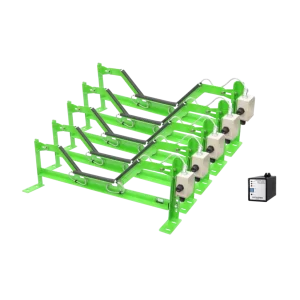

Mechanism that allows trough angle to be freely adjusted is adopted in consideration of on-site installation. Since there is no need to lift belt, chain blocks are unnecessary and can be easily installed and removed. Work time can be reduced to 1/2 or less compared to conventional method. - Wiring:

A maximum of 5 sensors can be attached to one converter. Since converter uses contact hold output, once an operation is detected, contact output continues unless the reset button is pressed to cancel or the power is turned off . Connected in series, when a disconnection accident occurs in connection cable or switch, disconnection detection is output immediately. - Adjustment:

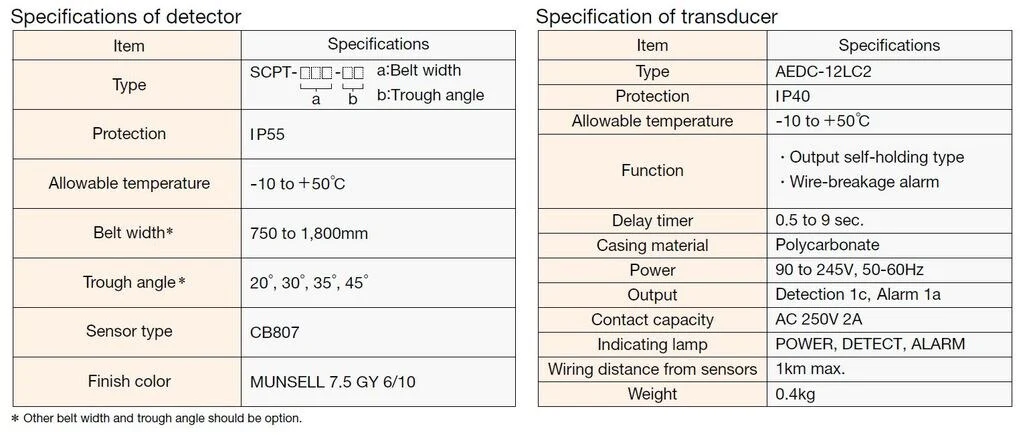

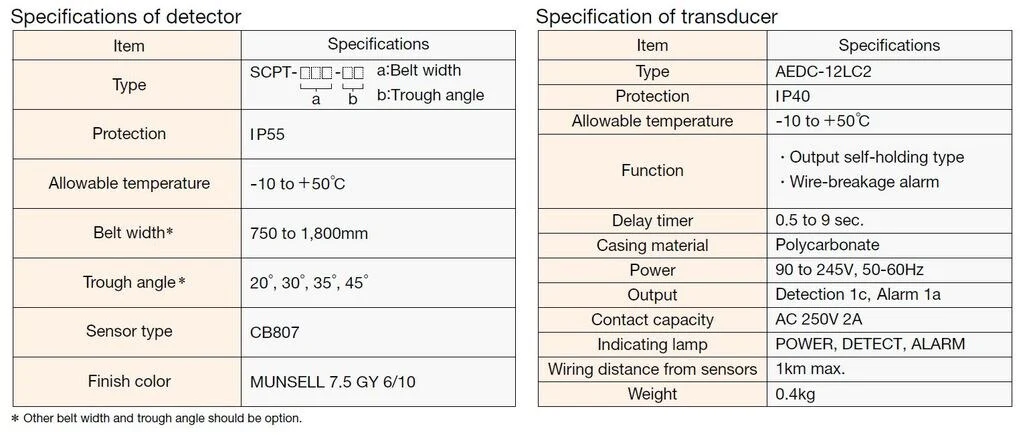

Specifications:

This is a type with fixed trough angle (fixed at specified angle).

Please inquire about trough angle adjustable type.