Advantates

- Out-of-load can be detected in advance to avoid quality defects in subsequent processes.

- It can also be used to predict clogging and overflow of conveyor transfer chutes.

- When transporting multiple raw materials on a single conveyor, mixing of raw materials can be avoided because the next raw material can be added after confirming that the load is completely exhausted.

- Detecting that a load has arrived at a certain position on the conveyor and activating the conveyor in the post-process will lead to energy saving.

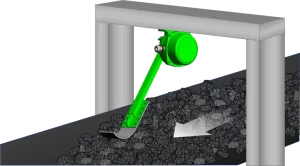

Operating principle

Install the detection vane as shown in the figure in the direction of the load flow. The detection lever tilts when there is a load on the belt conveyor. Depending on the tilt angle, the contact will be output to inform you. It supports 2 contact outputs, and the detection angle and contact output are as follows.

- Contact output 1: ON at 15° or more (for NC connection)

- Contact output 2: OFF at 60° or more (in the case of NC connection), the detection angle becomes 0° when there is no load.

Specifications: